PHOMI HOLDING, forerunner of eco-environmental material science! Founded in 2008, focusing on the research, development and production of econiclay based materials, we are committed to providing carbon-neutral material solutions to the world. With start-up mentality we develop up-to-date, sustainable material solutions for new challenges of living on our planet. We use modern technologies of the digital age, combine them with the knowledge of traditional Handcraft ship to create sustainable, ecofriendly and inspiring materials for the humans in the centerpiece of our minds. As an technical enabler, we give our material solutions and knowledge to partners to spread it worldwide. How to benefit the entire world with increasing application possibilities of econiclay products, is the responsibility we assume for society and human future.

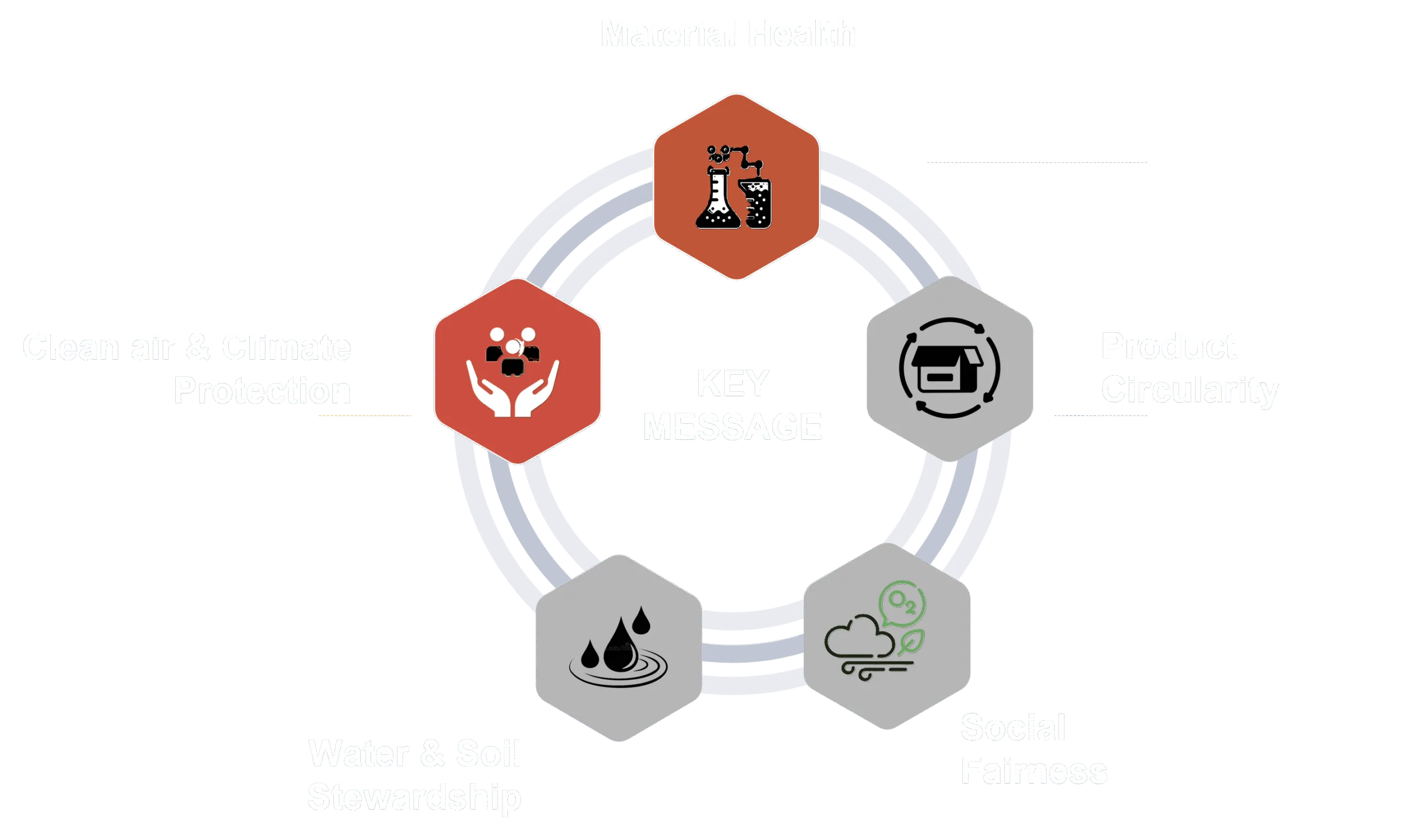

The econiclay products boast a Class A fire rating, enhancing fire safety in application areas and thereby increasing community safety, ultimately contributing to social equity.

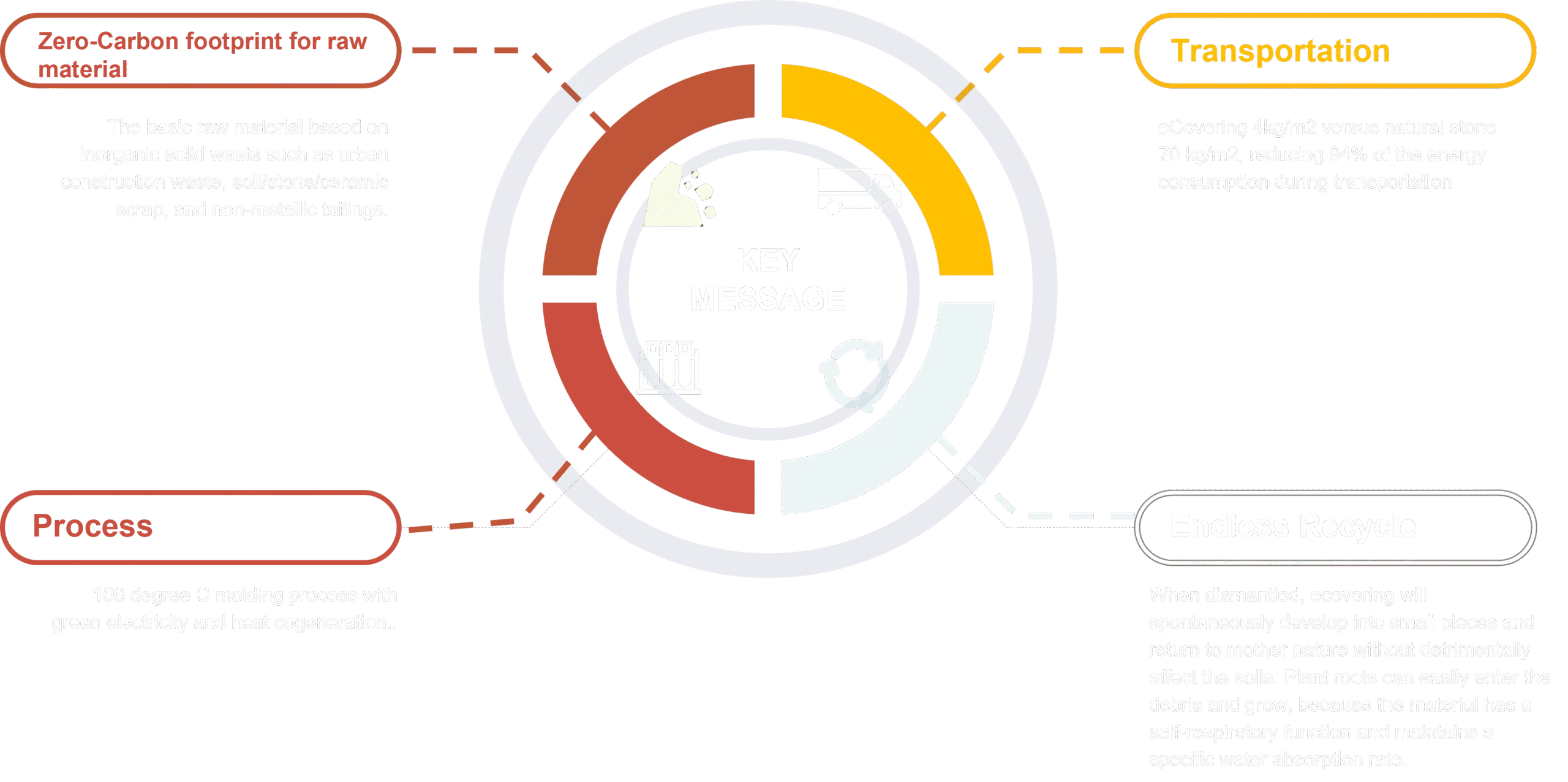

econiclay uses natural materials such as soil, stone waste, and non-metallic tailings as its raw materials. A meticulous process of collection, sorting, and screening ensures the quality of these materials. After being transformed into micro-level powders, specialized surfactants are applied to create a protective, multi-layered network structure, effectively preventing the release of harmful substances. This commitment to material quality guarantees that econiclay products are free from any harmful residues or emissions.

The econiclay products are easy to recycle for reuse after they’re no longer preferred. They don’t break down into harmful substances, making recycling practical. Mixing econiclay with other materials can create durable and flexible products, reducing the need for plastic and extending product lifespans. This conserves resources and supports recycling.

Our plant uses self-generated green electricity/steam as energy source and produce at low temperatures, reducing reliance on fossil fuels and helping decrease greenhouse gas emissions. The entire production process is environmentally friendly with no smoke, harmful gases, or wastewater released. econiclay’s inorganic properties ensures that it doesn’t emit harmful gases during use or recycling, contributing to cleaner air.

The econiclay production process conserves water resources by utilizing steam, which is efficiently transformed into production water during the condensation process. Simultaneously, the production process generates zero wastewater, making a positive contribution to the conservation of water resources. Importantly. econiclay products, being non-vitrified inorganic materials, have no detrimental impact on the soil after their lifecycle concludes, ensuring the long-term health of the land.

The production process of econiclay products is designed to minimize waste, noise, and the release of harmful substances, ensuring that both workers and neighboring communities are not negatively impacted by hazardous materials or poor environmental conditions. Utilizing low-temperature manufacturing and self-generated green electricity/steam as an energy source also helps reduce environmental pollution, fostering social equity. Implementation of carbon-neutral measures further supports social sustainability.

MCM products were applied as high way pavement in Mexico, building facades, and sports track. .

Phomi MCM was highly evaluated on the 112-d Paris International Investment Exhibition in 2013. Phomi MCM dedicated itself to changing lives & cities to live in a new sustainable low carbon way ..

Iconic projects were accomplished such as Northwestern Polytechnical University Campus (260,000 sq/m), 5 start Rosewood Hotel (50,000 sq/m).

We are the inventor of Phomi MCM, establishing EOSD laboratory in the United State and launching the researching program of MCM

MCM technology is widely used in Chinese construction. Phomi MCM was granted Hitech enterprise authenticated. .

The 3rd production base was opened in Laibin, Guangxi province to increase our total production to 60,000 sq/meter per year. The 1st showroom in Europe was opened in Czech Republic.